Snap-on needle-nose pliers with extra-long handles

Long-handled needle-nose pliers are typical tools that you only miss when you don’t have them at hand. They offer extra reach, create more leverage and provide better control in places you can’t reach with your hands. In compact technical environments, direct access is often limited and standard tools fall short. The Snap-on 915CF straight and 415CF curved needle-nose pliers with extra-long handles provide even more reach and control, allowing you to work more efficiently.

The 915CF with straight jaws and the 415CF with 35-degree angled jaws are both 15 inches long. This allows you to reach plugs, clips and components deep inside the vehicle without surrounding components getting in the way. This saves time and reduces the risk of damage.

Greater reach, greater control

The extra length allows you to work deeper into engine compartments, dashboards and chassis parts. The slim jaws and recessed hinge connection ensure that you maintain good visibility and control even in confined spaces. You can work precisely without first having to dismantle other parts of the vehicle.

Because the handles of Snap-on needle-nose pliers are torsion-resistant and do not bend, the hand force is transferred almost entirely to the hinge and jaws. With pliers whose handles deform, some of that force is lost. Not here.

This creates up to 85 per cent more effective gripping force at the tip, with even pressure distribution and less slippage on the component. Small plugs, clips and metal pins remain securely in place, making work more accurate and reducing the risk of damage.

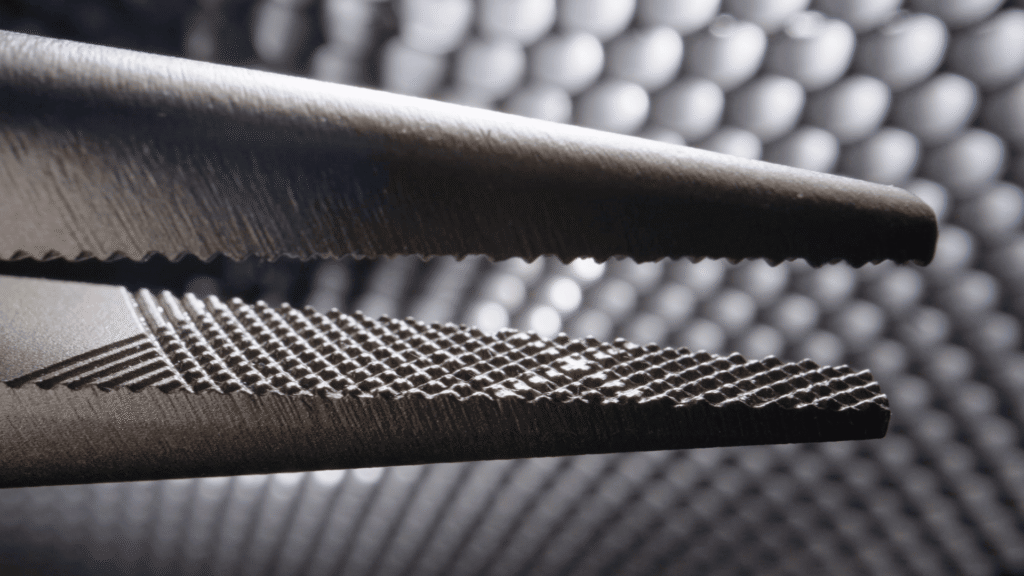

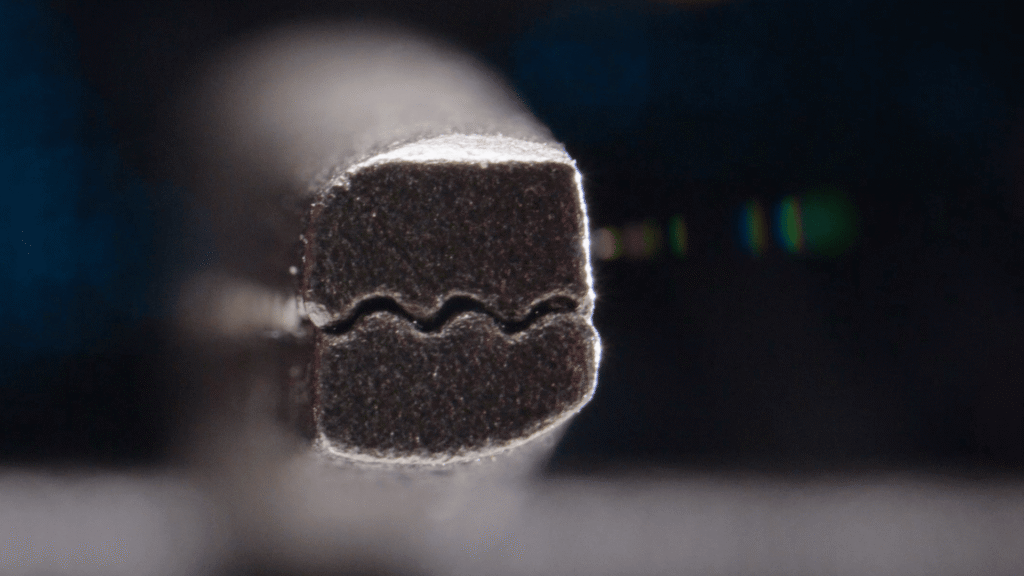

Teeth that bite down

The jaws feature Talon Grip diamond teeth. These are sharply milled teeth that bite into the material. This gives you up to 57 per cent more pulling power than with standard needle-nose pliers.

In practice, this means that a smooth clip, metal pin or small cable lug will remain securely in place. You do not need to keep reattaching or adjusting it.

The pliers are made of special cold-forged steel with a higher alloy content. This makes them stronger and more wear-resistant. Even after extensive use, the points remain straight and the teeth sharp. These are tools built for everyday use in the workshop.

Which pliers should you use when?

The 915CF with straight jaws is used when you can work directly on the component. Examples include plugs behind the intake manifold, vacuum hoses, fuel lines and locking pins in electrical connectors. The 415CF with 35-degree angled jaws is ideal when you need to work at an angle. This is the case, for example, with clips behind dashboards, cables along the bulkhead and hose clamps behind a turbo or EGR unit. Together, these two pliers form a combination that allows you to reach almost any difficult spot in modern vehicles.

If you need to remove or loosen a small locking clip behind a high-voltage module or ABS unit, there is often very little room for your hands. With standard pliers, you can easily slip. With the Snap-on needle-nose pliers with extra-long handles, you can reach deep into the compartment and pull the clip out in a controlled manner without slipping.

This extra length is also essential for lambda probe connectors behind the engine block or in hybrid powertrains. Where work would otherwise be time-consuming and cumbersome, the Snap-on 915CF and 415CF enable efficient and controlled work. These are not luxury tools, but targeted problem solvers for modern, compact vehicles. They give you more reach, better grip and maximum control in places where it would normally be difficult.

Would you like to experience this for yourself? Then contact your local Snap-on dealer and try them out in your own workshop.

Would you like to know more about this article?

Please contact us