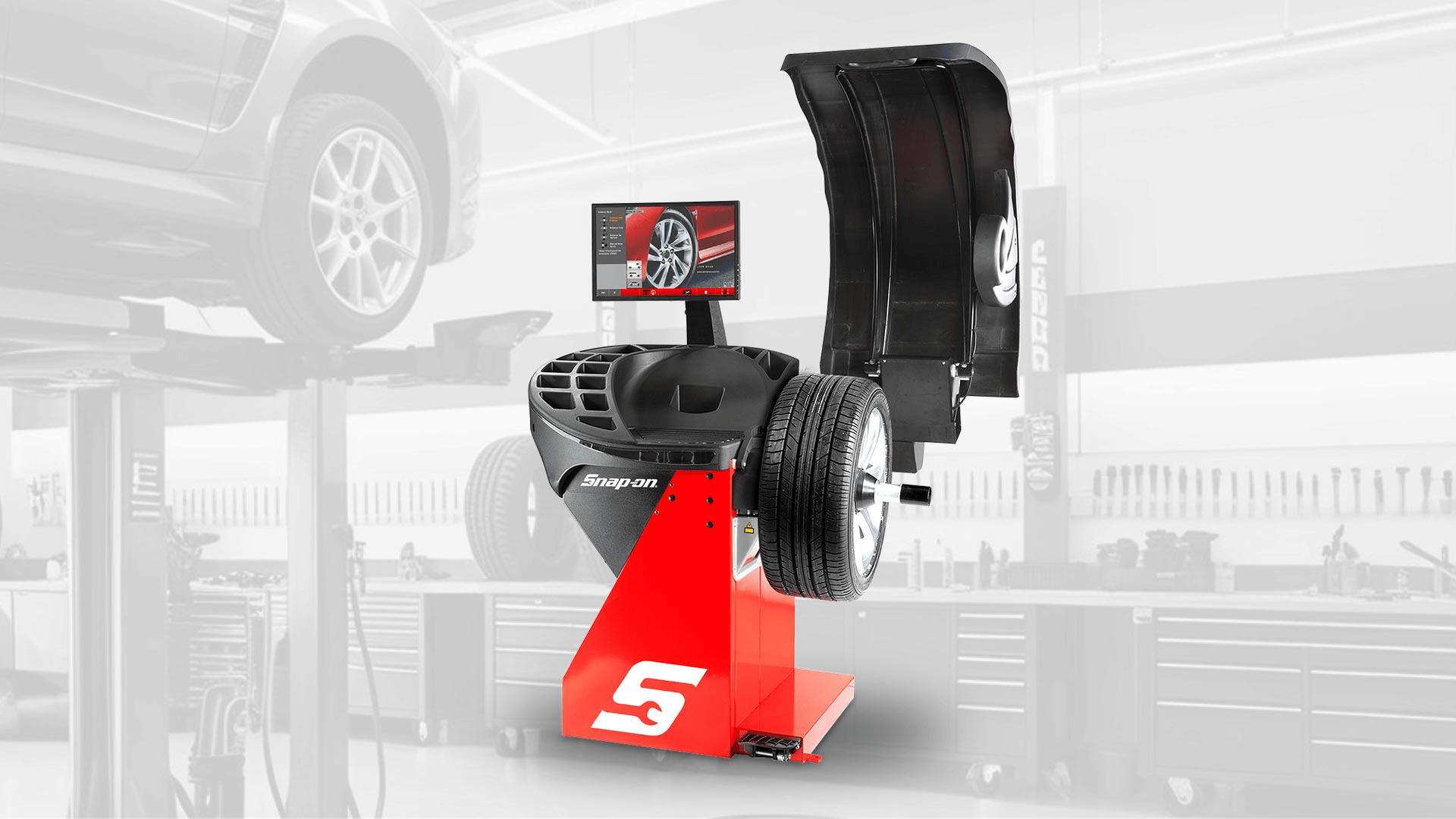

Diagnostic balancing machine detects minute imbalance

Balancing modern wheels requires sophisticated equipment that accurately detects the very smallest deviations. The Snap-on EEWB336AEA fully automatic diagnostic balancing machine goes beyond conventional balancing machines by measuring additional parameters such as radial force variation, eccentricity and lateral forces.

The Snap-on EEWB336AEA fully automatic balancing machine detects rim diameter, wheel distance and weight type without manual input. This makes balancing not only faster, but also more accurate and reliable. Thanks to advanced technologies such as automatic spoke detection, radial force measurement and height stroke analysis, even the smallest imbalance is detected and corrected.

User-friendly and practical balancing

With intelligent features such as smartSonar, easyWeight and QuickBAL, the EEWB336AEA balances more efficiently than ever. The machine automatically scans the rim width, indicates the exact correct weight position via laser and optimizes the number of revolutions per wheel. This prevents errors, saves time and increases accuracy.

An important feature of the EEWB336AEA is that the machine can balance (eliminate) height deflection without having to unload the tire from wheel and rotate it relative to the wheel. This saves considerable time. The Power Clamp provides constant clamping force, ensuring wheels are always perfectly secured for repeatable and precise measurements.

The intuitive touchscreen and bright LED lighting make the EEWB336AEA easy to operate, even during heavy use. Weights can be neatly hidden behind the spokes with Split Weight Mode, preserving the appearance of the rim. Reports can be printed directly or saved as PDFs. In short, this machine is a must-have for workshops that want to combine quality and speed in their wheel service.

The touchscreen interface makes operation quick and easy. Thanks to large symbols and colored position indicators, you can see at a glance where to place the weights. This not only increases speed and accuracy, but also ease of use and ergonomics for daily intensive use.

In addition, the machine offers extensive reporting capabilities. Results can be printed directly over the network or saved as PDFs, so you always have a clear overview of the work performed.

If you recognize one or more of the imbalance problems listed below, the Snap-on diagnostic balancer can fix it.

Designed for professionals who want highly accurate balancing, the Snap-on EEWB336AEA is the perfect choice to maximize workshop wheel service productivity and profits.

Want to know more after reading this article?

Neem contact op